TILBURY (Essex) - 01375 851111

office@ambahydraulics.co.uk

FELIXSTOWE (Suffolk) - 01394 673830

felixstowe@ambahydraulics.co.uk

IDENTIFYING A HOSE ASSEMBLY

IDENTIFYING HOSE TYPE

Look for markings on the hose.

These normally run along the lay line of the hose and will contain information such as hose type, SAE reference (R7, 4SP, 2SC, etc), bore size (I.D.) in either Imperial or metric,W.P. (working pressure), batch number, manufactured date.

We are looking primarily for

- Hose type

- Bore size

- SAE reference

- Working pressure (PSI, BAR, MPa)

IDENTIFYING THE THREAD TYPE

The most common types of threads used on hydraulic hose assemblies are BSP, ORFS, JIC, METRIC & FLANGE TYPE.

These can range in size,orientation(straight, 45° & 90°) and gender (male or female), hose tail size

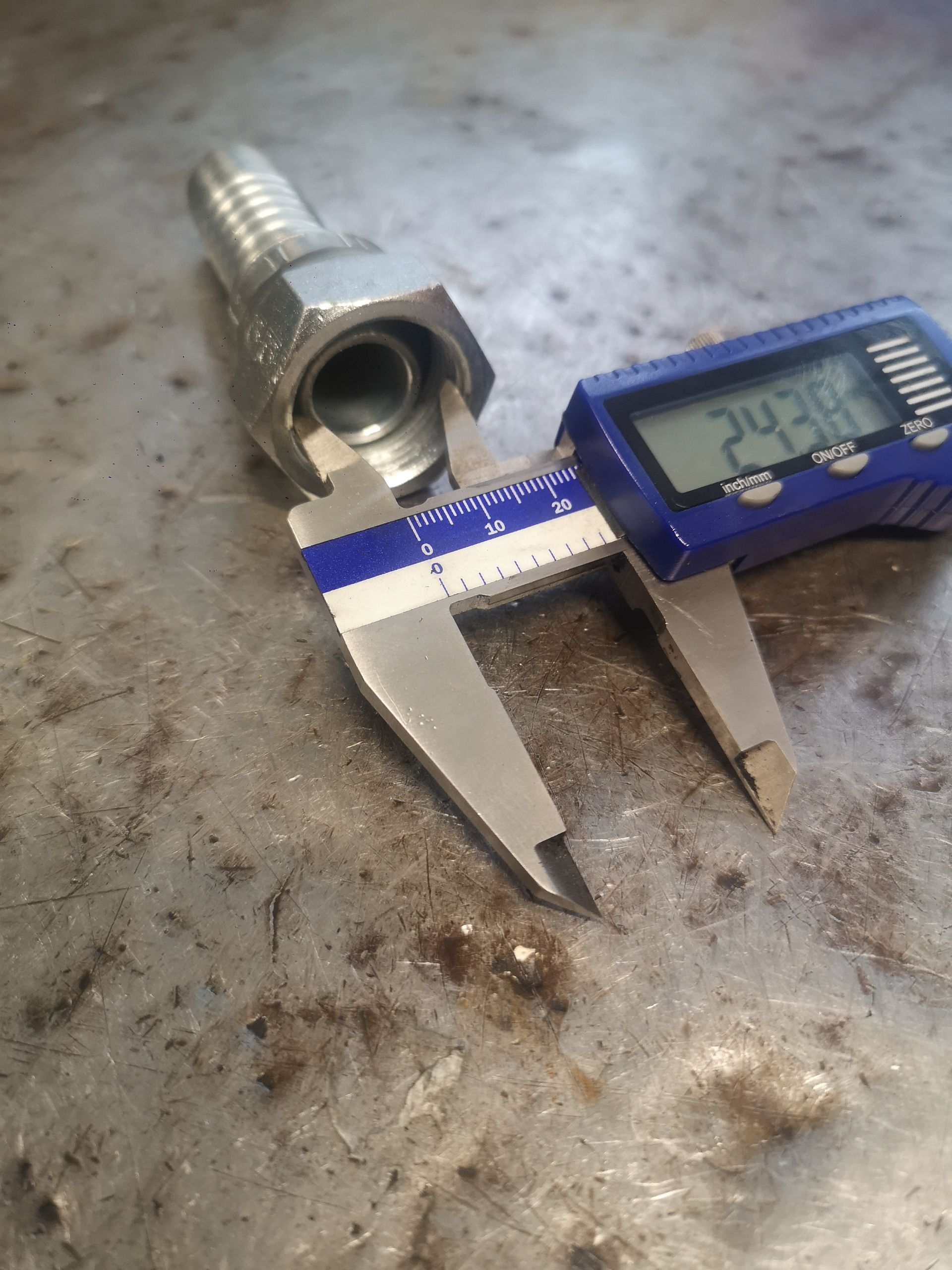

Not everyone has access to thread gauges but most will have a tape measure or vernier calipers.

These can be used to measure the internal thread on a female fitting or external thread on a male fitting or outside diameter & thickness of flange.

To establish the fitting type we need to look at what type of cone it has.

BSP- 60° CONVEX CONE (POINTS OUTWARDS)

JIC-37° CONCAVE CONE (POINTS INWARDS)

ORFS-FLAT FACE WITH NO CONE

METRIC-24° CONVEX CONE (POINTS OUTWARDS,NORMALLY WITH O'RING)

FLANGE- NON THREADED FLAT FACE FITTING WITH O'RING RECESS. HELD ON BY 2 X CLAMP HALVES.

MEASURING AN ASSEMBLY

To get an accurate measurement of the complete assembly, measure from end face of fitting (1) to end face of fitting (2), if there is a 90° or 45° fitting then measure to center of the fitting (as depicted in picture below).

This method of measuring ensures correct overall length regardless of different manufacturers length of fittings.